Pros and Cons of Heavy Timber Construction

Heavy timber construction is having a moment.

You see it in luxury mountain homes. In modern commercial spaces. Even in schools, churches, and public buildings. There’s something about exposed wood beams that stirs the soul. It’s raw. It’s warm. It feels alive.

But behind the beauty lies a big question—

Is heavy timber the right choice for your project?

Architects, builders, and property owners are weighing the pros and cons. The upfront cost. The structural perks. The environmental impact. The fire safety. The maintenance headaches.

And that’s where we come in.

At Tuscarora Timber Frame, we’ve walked hundreds of clients through these exact questions. We love timber—but we also know it’s not for every build. In this guide, we’ll unpack the real-world advantages and limitations of heavy timber construction. No fluff. No sugar-coating.

Just clear insight to help you make the best choice for your project.

Let’s dive in.

Cost Comparison: Upfront vs. Long-Term Value

Let’s start with the elephant in the room—cost.

Yes, heavy timber construction usually costs more up front. The materials aren’t cheap. And it takes specialized labor to cut, fit, and raise those big beams. Compared to stick framing or even steel, you’ll likely pay a premium at the beginning.

But here’s what many people overlook:

- Fewer finish materials. With timber, the structure is the finish. No need to hide it behind drywall.

- Energy efficiency. Pairing heavy timber with SIPs (Structural Insulated Panels) can lead to tight, well-insulated homes that cost less to heat and cool.

- Longevity. Heavy timber buildings are built to last—think generations, not decades. That means fewer renovations and replacements over time.

So is it more expensive? On paper—yes.

But when you factor in aesthetics, efficiency, and lifespan? The long-term value is hard to beat.

That’s why many of our clients at Tuscarora are willing to pay more up front and never look back.

Structural Strength & Durability

Heavy timber isn’t just pretty. It’s strong.

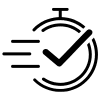

These massive wood beams can carry serious loads. We're talking wide-open interiors with tall ceilings, fewer support posts, and long-lasting stability.

Here’s what makes it stand out:

- Load-bearing power. Properly sized timbers can support large roof spans and second-story loads with ease.

- Natural resilience. Timber is flexible under stress, which makes it great for seismic zones and high-wind areas.

- Time-tested durability. There’s a reason timber frame buildings from the 1800s are still standing.

But there are limits.

- Span restrictions. Go too wide without engineered wood or steel, and you may hit structural limits.

- Settling and shrinkage. Like all wood, heavy timbers can shift slightly as they dry, which must be accounted for in the design.

Bottom line?

When designed correctly, timber frames can last for centuries. It’s not just about looking good now. It’s about standing strong for generations.

Sustainability & Environmental Impact

If sustainability is on your radar, heavy timber deserves a close look.

Unlike steel or concrete, wood is renewable. It’s grown, not mined or forged. And when responsibly sourced, it can actually help reduce a building’s environmental footprint.

Here’s why:

- Carbon storage. Trees absorb carbon. When used in buildings, that carbon stays locked in the timber—for decades or even centuries.

- Lower embodied energy. It takes less energy to process wood than to manufacture steel or concrete.

- Renewable resource. With proper forest management, timber can be harvested and replanted indefinitely.

- Certifications available. Many suppliers offer FSC-certified wood that ensures responsible sourcing.

But—there’s a flip side:

- Not all wood is equal. Sourcing matters. Unsustainable logging practices can harm forests and communities.

- Shipping impacts. Hauling massive beams long distances can raise the carbon footprint, especially if you’re importing exotic species.

That’s why we source as locally and responsibly as possible at Tuscarora Timber Frame. We believe a beautiful frame shouldn’t come at the planet’s expense.

Timber can be a powerful part of building green—if you do it right.

Fire Performance: Surprising Strength Under Pressure

Here’s a twist most people don’t expect…

Heavy timber performs remarkably well in fire.

It might seem counterintuitive—after all, it’s wood. But large timbers don’t ignite like kindling. They char on the outside, which actually protects the core.

Here’s how it works:

- Predictable charring. As the surface burns, it forms a protective layer that slows further damage.

- Maintains integrity longer. Unlike steel, which can bend or collapse under extreme heat, heavy timber often remains structurally sound.

- Code-compliant. Many jurisdictions recognize heavy timber as a valid fire-rated material in Type IV construction.

But there are still things to consider:

- Engineered testing may be required. Especially in commercial builds or urban zones.

- Insurance complexity. Some insurers may need extra documentation to understand the fire behavior of exposed wood.

The good news?

We’ve worked with engineers and inspectors to walk clients through fire performance details—many are surprised (and relieved) by how well timber stacks up.

Timber framing isn't just about designing for beauty—it's about designing for resilience.

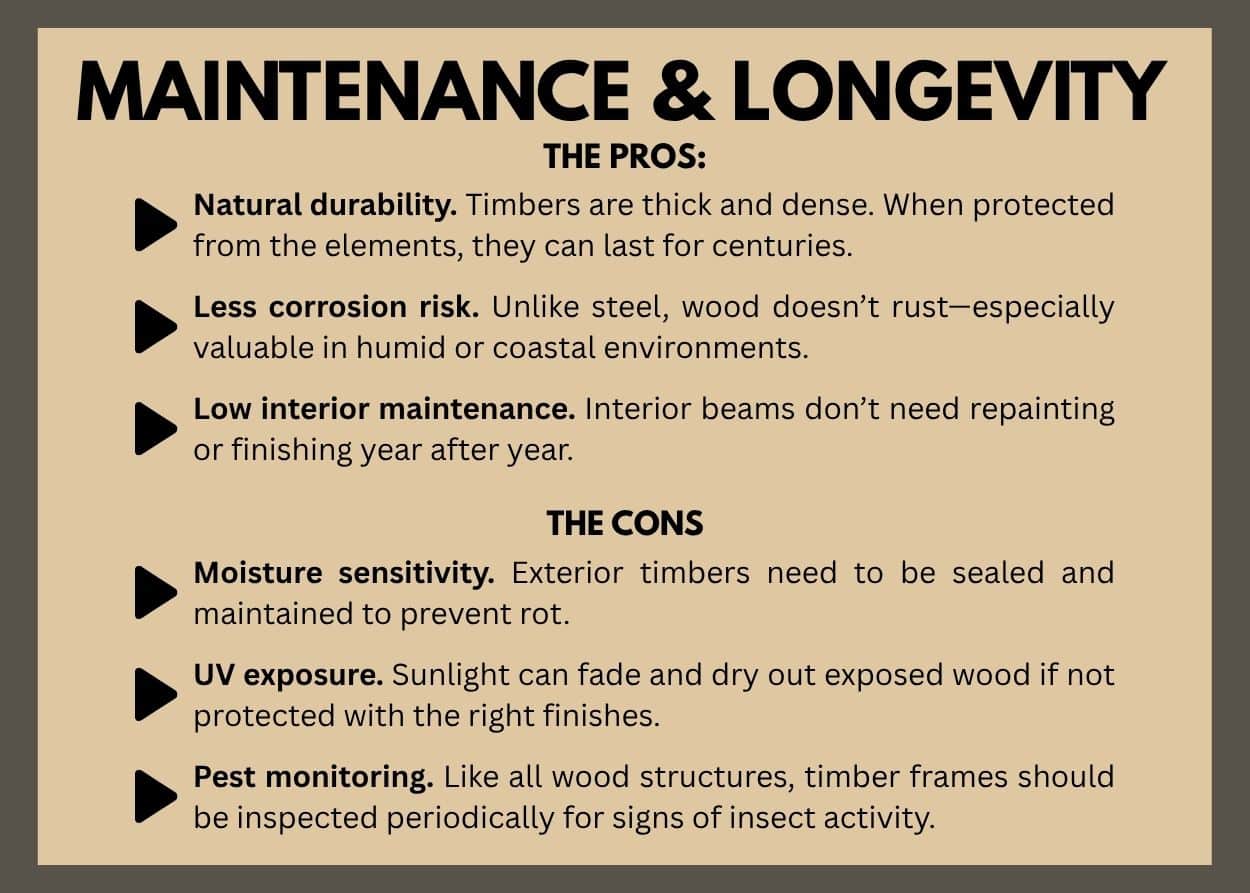

Maintenance & Longevity

Now let’s talk about upkeep.

Heavy timber structures are built to last. But like anything worth keeping, they need care.

The pros:

- Natural durability. Timbers are thick and dense. When protected from the elements, they can last for centuries.

- Less corrosion risk. Unlike steel, wood doesn’t rust—especially valuable in humid or coastal environments.

- Low interior maintenance. Interior beams don’t need repainting or finishing year after year.

The cons:

- Moisture sensitivity. Exterior timbers need to be sealed and maintained to prevent rot.

- UV exposure. Sunlight can fade and dry out exposed wood if not protected with the right finishes.

- Pest monitoring. Like all wood structures, timber frames should be inspected periodically for signs of insect activity.

Thankfully, most of this isn’t intensive or expensive. It’s just about staying ahead of the game.

At Tuscarora Timber Frame, we coach our clients on protective finishes, proper ventilation, and long-term upkeep strategies.

Because beauty and strength mean nothing if they don’t last.

Construction Speed & Methods

Here’s something many builders love about timber:

It can go up fast.

But only if the prep is done right.

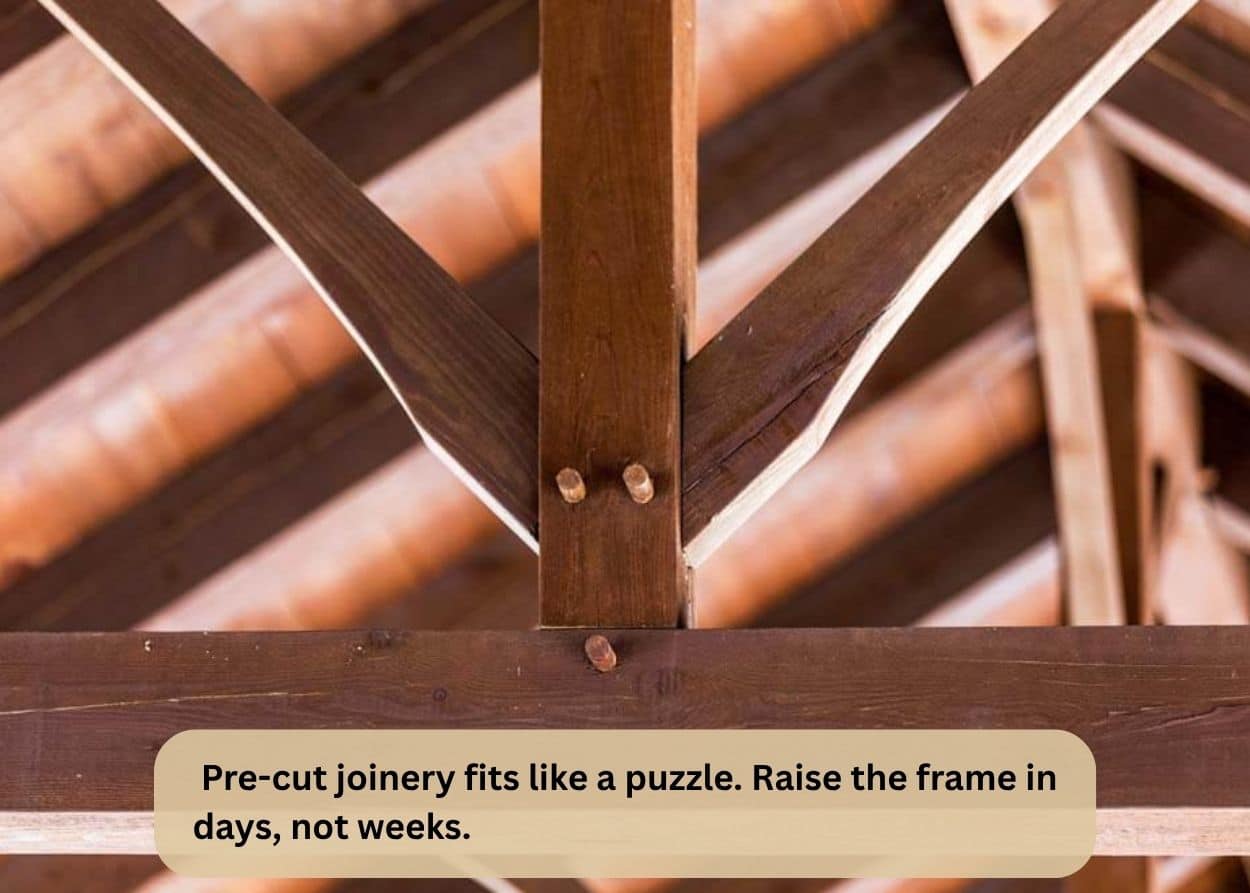

At Tuscarora Timber Frame, we use precision-cut, pre-engineered timbers—often fabricated off-site. That means when materials arrive, it’s go time.

The benefits:

- Quick assembly. Pre-cut joinery fits like a puzzle. Raise the frame in days, not weeks.

- Fewer trades. With a timber frame, there’s less need for extra framing crews or finish carpenters.

- Less waste. Off-site fabrication keeps the jobsite cleaner and more efficient.

But… it’s not always smooth sailing:

- Heavy lifting required. Timbers are big. You’ll need cranes and the right staging.

- Coordination is critical. One delay—like foundation issues or late deliveries—can throw off the whole timeline.

- On-site changes? Not easy. Every beam is cut to spec. Last-minute design changes are tough once the frame is on-site.

So yes, timber can speed things up. But only when there’s clear communication and precise planning.

That’s why we partner closely with builders and designers every step of the way—to keep things smooth, on schedule, and stress-free.

Limitations & Drawbacks

We love timber. But let’s be real—it’s not perfect.

There are a few practical challenges you should weigh before committing.

Common limitations:

- Span restrictions. Want huge open spaces without posts? You may need to add steel or engineered wood.

- Skilled labor. Not every crew knows how to raise a timber frame. It’s a craft—and not every builder is trained in it.

- Moisture risks. Timber can absorb water. Without proper flashing, sealing, and ventilation, you can end up with rot or mold issues.

And availability matters too.

Material sourcing. Big timbers aren’t always in stock at your local yard. Lead times can vary depending on species and size.

The solution?

Plan ahead. Work with an experienced team. And think long-term, not just what’s easy today.

Is Heavy Timber Right for You?

Heavy timber construction is strong. Beautiful. Sustainable.

But it’s not one-size-fits-all.

If you’re after quick-and-cheap, it might not be the best fit.

If you want something that’s built to last, makes a bold architectural statement, and reflects your values of quality and stewardship—then heavy timber is worth serious consideration.

Let’s Build Something Worth Remembering

At Tuscarora Timber Frame, we help homeowners, architects, and builders bring their timber frame visions to life.

From design to delivery, we guide you every step of the way.

Want to explore what’s possible for your project?

Contact us here to start the conversation.

And if you'd like to learn more about heavy timber framing, check out the following articles: