How Timber Frame Homes Are Built: From Raw Lumber to Finished Structure

Walk into a timber frame home, and you feel it right away.

The calm.

The strength.

The story.

There’s something grounding about exposed beams overhead. Something ancient. Like you’ve stepped into a space that isn’t just built—it’s crafted.

At Tuscarora Timber Frame, we’ve spent years perfecting the art of turning raw logs into beautiful, long-lasting timber structures. In this post, we want to pull back the curtain and show you what really goes into the process—from selecting the right tree to raising the final frame.

Because these buildings aren’t just functional. They’re heirlooms.

What Makes Timber Framing So Different?

Let’s start with the basics.

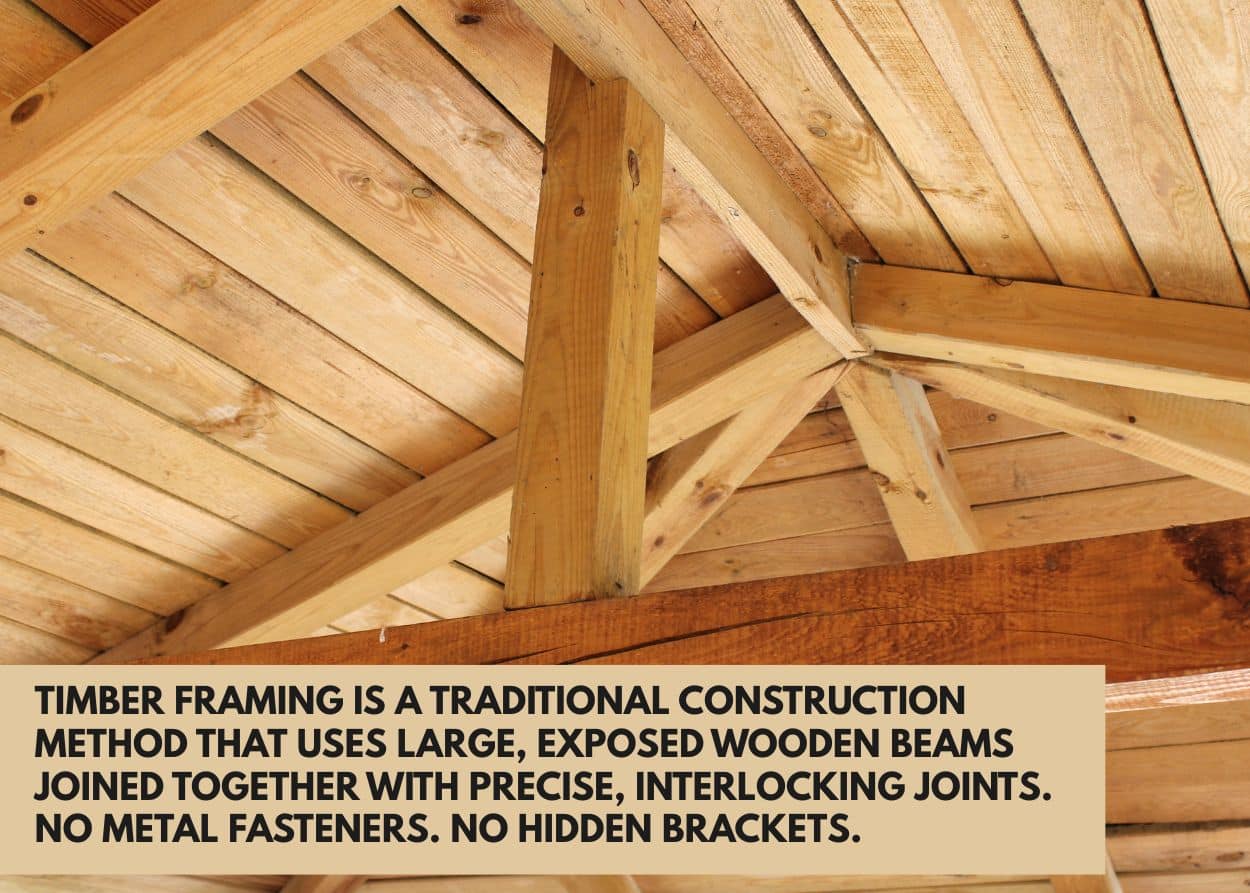

Timber framing is a traditional construction method that uses large, exposed wooden beams joined together with precise, interlocking joints. No metal fasteners. No hidden brackets.

Just wood… holding wood.

That’s different from standard framing, where 2x4s and nail guns rule the day. In conventional builds, the structure gets hidden behind drywall. In timber framing, the structure is the design.

It’s open. Honest. Timeless.

And it’s not new. This method goes back centuries—used in European cathedrals, colonial barns, and ancient temples. The fact that so many of those structures are still standing says a lot.

From Forest to Frame: Our Step-by-Step Process

We don’t just build frames. We build stories. And every good story starts with the raw material.

1. Lumber Selection

Everything begins with the wood.

We’re picky about what we use. The species, the grain pattern, the moisture content—it all matters. Some projects call for white oak. Others for Douglas fir or hemlock. Each has its own character.

But one thing’s consistent: we source with integrity. That means sustainable forests, local mills when possible, and a commitment to honoring the land these timbers come from.

2. Milling & Seasoning

Once we’ve got the right logs, they head to the sawmill to be cut into square timbers.

But before we can cut joinery, the wood needs to settle. Wood moves as it dries. Twists. Shrinks. Cracks. We want as little of that as possible once your frame is up.

That’s why we air-dry or kiln-dry each beam. It’s not the fastest route, but it’s the right one.

3. Layout & Joinery Design

Next comes the layout phase.

Every beam gets a detailed plan. We use both traditional techniques—like scribing and square rule—and modern CAD software to make sure every piece fits like a glove.

We’re not just slapping boards together. We’re crafting joints that will hold for a hundred years or more.

Mortise-and-tenon. Dovetails. Scarf joints. Each joinery type serves a purpose—balancing load, handling stress, and allowing the frame to breathe.

4. Cutting & Shaping the Timbers

Now the fun begins.

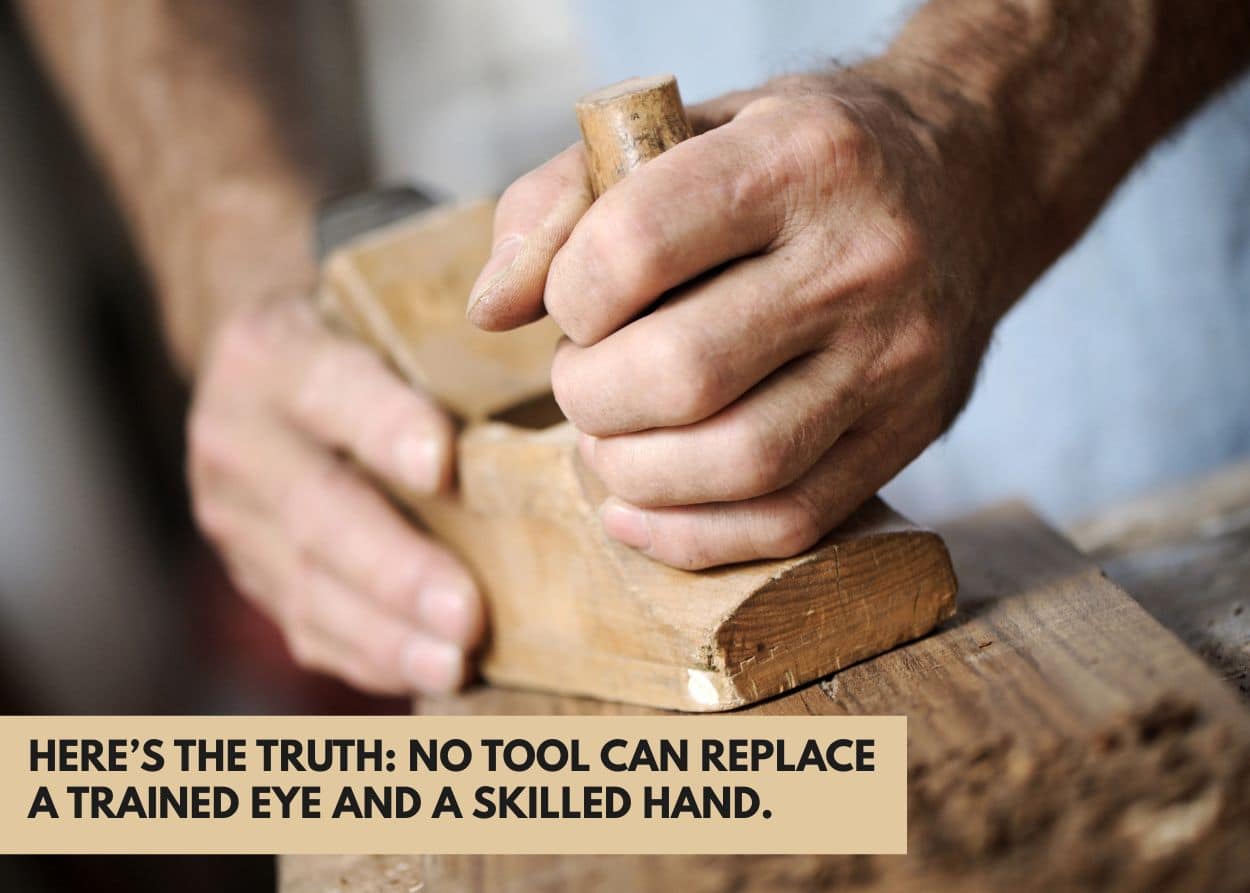

This is where craftsmanship really shines. Our team starts shaping each beam by hand or with precision tools, depending on the project. You’ll find us using chisels, slicks, mallets, and layout squares. And yes, we’ve got power mortisers and band saws in the shop too—because some days, speed matters.

But here’s the truth: no tool can replace a trained eye and a skilled hand.

Every cut is checked. Every joint is test-fit. Every beam is respected.

5. Test Fitting & Finishing Touches

Before anything heads to your site, we do a dry fit in our shop. Like a puzzle laid out on the floor.

This gives us a chance to catch any tweaks before the frame goes vertical. Once it all lines up, we sand the timbers, chamfer the edges, and drill peg holes. Sometimes we’ll pre-finish the wood with oils or stains, depending on your design.

Details matter here. Because when the light hits your finished frame just right, it should sing.

6. Frame Assembly on Site

Finally, we transport the finished timbers to your site.

This is what we call the “raising”—and it’s one of our favorite days. The crane hums. The team moves with precision. Joints slide into place, pegs are driven home, and the frame rises into the sky.

It’s hard not to feel a little awe in those moments.

You’re not just watching a structure go up. You’re watching legacy take shape.

The Tools & Techniques That Bring It All Together

We’re often asked if we use traditional or modern tools. The answer? Yes.

We love our chisels and mallets. We love our routers and sanders too. It’s not about old vs. new—it’s about using the best tool for the job.

Some joints are best cut by hand. Others benefit from a CNC machine that can shave hours off the timeline without sacrificing accuracy.

But no matter the tool, the heart behind it stays the same: care, precision, and pride in the craft.

Why Timber Frames Stand the Test of Time

Here’s the thing: Timber frames aren’t just beautiful. They’re built to last.

Why is that? Well, let’s break it down:

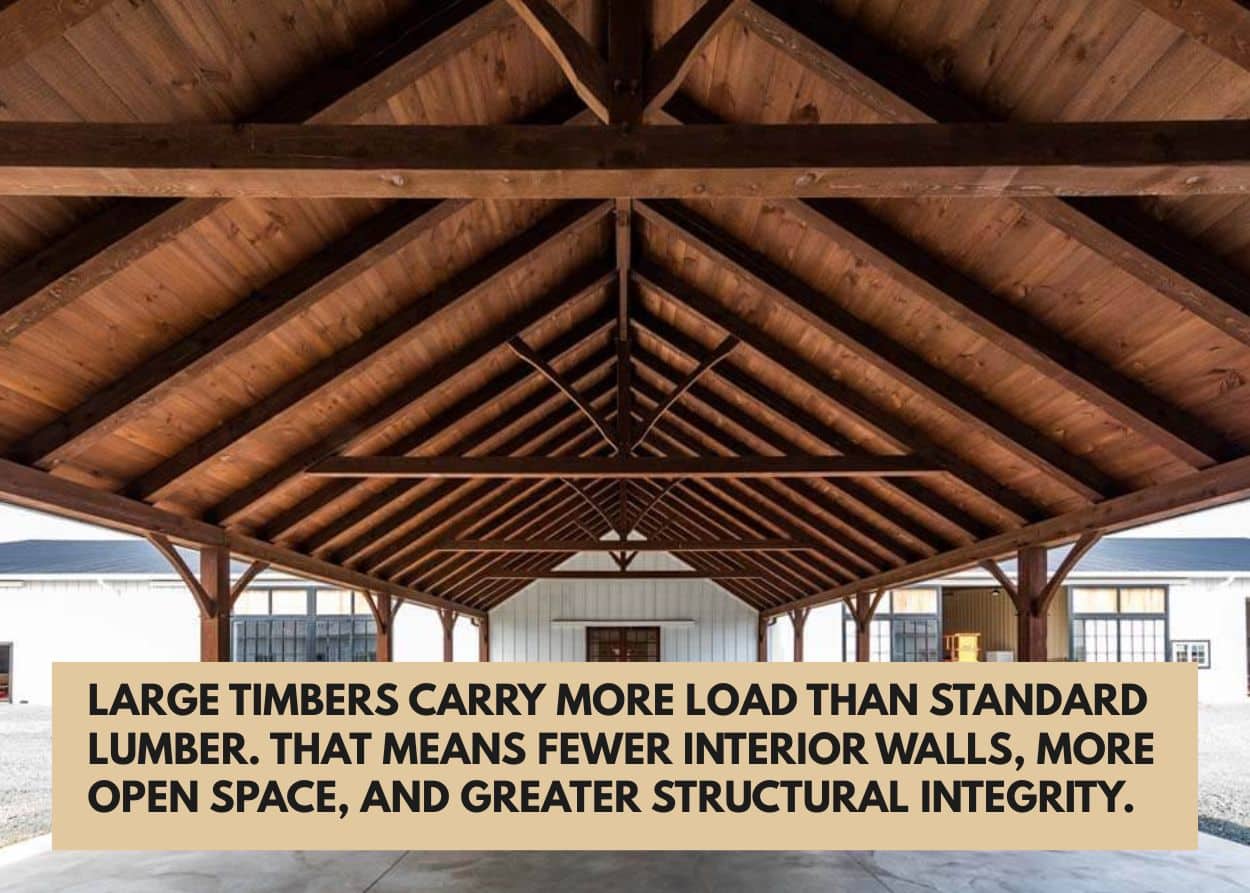

- Strength: Large timbers carry more load than standard lumber. That means fewer interior walls, more open space, and greater structural integrity.

- Durability: These frames can flex with wind and settle with the land. That’s why they perform well in earthquakes and storms.

- Fire Resistance: Large beams actually only char on the outside but stay structurally sound much longer than small dimensional lumber.

- Low Maintenance: A well-built timber frame needs less upkeep over time.

In other words, this isn’t throwaway construction. It’s generational.

Where Timber Framing Shines

So where do timber frames belong?

Honestly… anywhere you want timeless beauty and lasting strength.

- Custom homes: Open floor plans. Cathedral ceilings. Exposed beams that wow.

- Cabins: Rustic, warm, and ready for snowy mornings and summer evenings alike.

- Barns & outbuildings: Strong enough for tractors. Beautiful enough for weddings.

- Pavilions & event spaces: Bring the outdoors in with structures that don’t just host events… they elevate them.

Whatever you're building, a timber frame gives it soul.

Closing Thoughts: Why We Do This Work

At Tuscarora Timber Frame, we’re not just carpenters. We’re craftsmen. Builders. Storytellers.

We believe a home should do more than keep the weather out. It should invite people in.

It should reflect the land it’s built on—and the people it’s built for.

That’s what timber framing does. It connects the past to the present. Tree to timber. Craft to calling.

And if you’re dreaming of a space that tells a story—we’d love to help you build it.

→ Explore our project gallery or get in touch to start your own timber frame journey.